How to Band a Pallet: Tips from the Experts

Pallet banding is a crucial step in securing shipments for safe and efficient transport. Whether you're a seasoned shipping professional or a small business owner, understanding how to properly band a pallet is essential for preventing damage, minimizing losses, and maintaining customer satisfaction. This comprehensive guide offers expert tips and techniques to ensure your pallets are banded correctly every time.

Why is Pallet Banding Important?

Before diving into the how-to, let's emphasize the why. Proper pallet banding is crucial for several reasons:

- Product Protection: Secure banding prevents shifting and damage to goods during transit, protecting your investment and ensuring the integrity of your products.

- Load Stability: Well-banded pallets are less likely to topple or collapse, reducing the risk of accidents and damage during handling and transportation.

- Reduced Shipping Costs: Minimizing damage translates directly to lower insurance claims and replacement costs.

- Improved Efficiency: Proper banding speeds up loading and unloading processes, streamlining your supply chain.

- Compliance: Many industries have specific regulations regarding load securing, and proper banding is often a requirement.

Choosing the Right Pallet Banding Material

The type of banding you choose is critical. Common materials include:

- Steel banding: Strong and durable, ideal for heavy or sharp-edged goods. It often requires specialized tools for application and removal.

- Polypropylene (PP) banding: Lighter and more flexible than steel, making it easier to work with. Often preferred for lighter loads and less demanding applications. Recyclable options are also readily available.

- Polyester (PET) banding: Offers a good balance between strength and flexibility, often chosen for its high tensile strength and tear resistance.

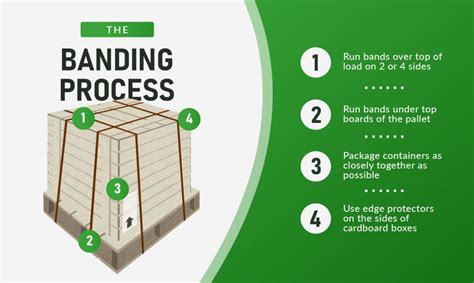

Step-by-Step Guide to Banding a Pallet

Here’s a detailed walkthrough of the process:

-

Assess the Load: Carefully inspect your pallet and its contents. Ensure the load is evenly distributed and stable before applying banding. Overly heavy items should be placed at the bottom. Identify any potential weak points.

-

Choose the Right Banding: Select the appropriate type and width of banding based on the weight and size of your pallet. Wider bands are generally stronger and more suitable for heavier loads.

-

Position the Banding Tool: For steel banding, you’ll need a specialized tensioner and sealer. PP and PET banding often use a simpler manual or semi-automatic tensioner.

-

Apply the Band: Wrap the banding material around the pallet, ensuring it's snug but not overly tight. Tension is crucial, but over-tightening can damage the pallet or goods.

-

Secure the Band: Use the appropriate sealing mechanism to fasten the band. With steel, this involves a sealer that crimps the ends. For PP and PET, it might be a buckle or a heat seal.

-

Inspect the Banding: Once banded, carefully examine the finished product. Ensure the banding is taut, evenly distributed, and securely fastened. Check for any signs of weakness or potential points of failure.

-

Repeat as Necessary: Depending on the size and weight of the load, you may need multiple bands horizontally, vertically, or both, creating a strong and secure structure.

Frequently Asked Questions (PAA)

What is the best type of pallet banding to use?

The optimal banding type depends on the specific requirements of your load. Steel banding provides superior strength for heavy or sharp items, while polypropylene and polyester are better choices for lighter loads or where ease of application is a priority. Consider the weight, dimensions, and fragility of the goods, as well as your budget and available equipment.

How much tension should I apply to the banding?

The correct tension is vital. Too little, and the banding won’t secure the load effectively; too much, and you risk damaging the pallet or goods. Consult the manufacturer's instructions for your banding material and tensioning tool for specific recommendations. Aim for a firm, even tension without undue stress.

Can I reuse pallet banding?

While you might be tempted to reuse banding, it's generally not recommended, particularly with steel banding. Repeated use can weaken the material, increasing the risk of failure during transit. Using fresh banding ensures the structural integrity of your shipment and minimizes the risk of costly damage or accidents.

How can I reduce the risk of pallet banding failure?

Several factors contribute to banding failure. Ensure you use the correct banding material for the load weight and dimensions. Apply even tension, properly secure the banding, and regularly inspect your tools and equipment to ensure they're in optimal working condition. Prevent overloading and ensure your goods are stacked appropriately and secured before banding.

What happens if I don't band my pallets correctly?

Improperly banded pallets lead to a higher risk of load shifting, product damage, and accidents during handling and transportation. This can result in costly repairs, replacements, delays, and potential injury. It also impacts your reputation and customer satisfaction.

By following these tips and addressing common concerns, you can ensure your pallets are securely banded, protecting your goods and maintaining a smooth and efficient shipping process. Remember, investing in proper banding techniques is an investment in the safety and success of your operations.