Sonit Check: Is Your Roll Bar Thick Enough?

For off-road enthusiasts, a roll bar is more than just a safety feature; it's a crucial element of vehicle integrity and survival. But how do you know if your roll bar is truly up to the task? A simple visual inspection isn't enough. This comprehensive guide delves into the critical factors determining roll bar thickness and strength, providing you with the knowledge to make informed decisions about your off-road safety. We'll explore the science behind roll bar design, address common concerns, and help you determine if your current setup provides adequate protection.

Understanding the Importance of Roll Bar Thickness

The thickness of your roll bar, often measured in diameter or wall thickness (depending on its construction), directly impacts its ability to withstand impact forces. A thicker bar possesses greater strength and stiffness, crucial in absorbing the energy from a rollover or significant impact. This strength is paramount because the roll bar is the last line of defense between you and potential serious injury or death. A flimsy roll bar, conversely, can fail under pressure, potentially exacerbating the situation.

What Factors Determine Necessary Roll Bar Thickness?

Several interconnected factors influence the required thickness of your roll bar:

-

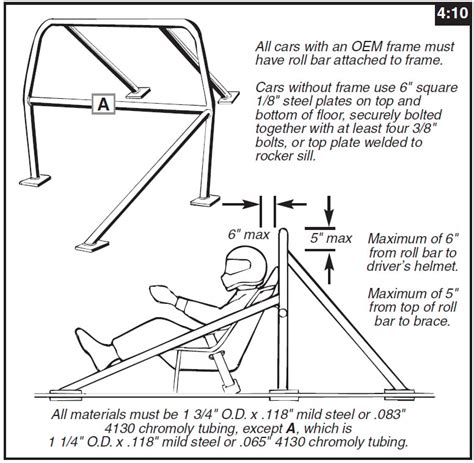

Material: Steel is the most common material, but its strength varies greatly depending on the grade. Higher-grade steel, like chromoly, offers superior strength and lighter weight compared to mild steel. The material's yield strength is a key specification to consider.

-

Bar Diameter/Wall Thickness: These are directly related to the bar's overall strength. Larger diameter bars with thicker walls naturally offer greater resistance to bending and deformation.

-

Vehicle Weight and Type: Heavier vehicles require stronger roll bars. A roll bar suitable for a lightweight dune buggy won't suffice for a heavy-duty rock crawler. The vehicle's center of gravity also plays a significant role.

-

Driving Conditions: The intensity and type of off-roading you engage in directly impact the stress placed on the roll bar. Extreme rock crawling requires a significantly stronger roll bar than casual trail riding.

-

Roll Bar Design and Mounting: The overall design of the roll bar, including its bracing and mounting points, significantly influences its effectiveness. A poorly designed or improperly installed roll bar, regardless of thickness, might fail under stress.

How to Assess Your Roll Bar's Strength

While a definitive assessment often requires engineering calculations and specialized software, here are some practical steps you can take:

-

Visual Inspection: Look for any signs of bending, cracks, or welds that appear compromised. Pay close attention to the mounting points.

-

Check Manufacturer Specifications: If you know the manufacturer and model of your roll bar, consult their specifications for recommended vehicle weights and usage.

-

Consult a Professional: If you have any doubts about your roll bar's adequacy, consult a qualified off-road vehicle fabricator or engineer experienced in roll cage design and safety.

What if My Roll Bar Isn't Thick Enough?

If you're concerned about the adequacy of your roll bar, upgrading is crucial. Don't attempt DIY modifications without expert guidance. Improper modifications can compromise safety even further. Contact a qualified professional to assess your vehicle and design or install a suitably robust replacement.

Frequently Asked Questions (PAA)

What is the minimum diameter for a roll bar?

There's no universally applicable minimum diameter. The appropriate diameter depends on the factors mentioned above: vehicle weight, material, driving conditions, and design. Consulting with an expert is crucial to determine the minimum diameter suitable for your specific setup.

How do I calculate the required roll bar thickness?

Calculating the precise required thickness demands detailed engineering analysis, considering factors like material properties, loading conditions, and safety factors. Software tools and expert consultations are necessary for accurate calculations.

What are the common signs of a failing roll bar?

Signs of a failing roll bar include visible bending, cracking, welding failure at mounting points, or any signs of deformation after impact. Regular inspections are vital to catch problems early.

Are there different standards for roll bar construction?

Yes, several standards and guidelines exist, though they vary regionally. Familiarizing yourself with relevant standards in your area is important when designing or selecting a roll bar.

Can I reinforce my existing roll bar?

Reinforcing an existing roll bar is possible but should only be performed by a qualified professional. Improper reinforcement can weaken the structure rather than strengthening it.

This article provides general guidance on roll bar thickness. Always prioritize safety and consult with experienced professionals for accurate assessments and modifications. Your safety is paramount.