Improve Steel's Corrosion Resistance: Adding Carbon? A Surprising Twist

The relationship between carbon content and corrosion resistance in steel is complex and often counterintuitive. While it's widely known that carbon significantly influences steel's strength and hardness, its impact on corrosion resistance is less straightforward. Adding carbon can improve corrosion resistance in some scenarios, but generally, higher carbon content leads to increased susceptibility to corrosion. Let's delve into this nuanced topic.

Does Adding Carbon Improve Steel's Corrosion Resistance?

The short answer is: not directly, and often the opposite. Higher carbon content typically makes steel more prone to corrosion. This is because carbon atoms can disrupt the steel's microstructure, creating areas where corrosion can more easily initiate and spread. These areas act as anodes, accelerating the electrochemical processes that lead to rust.

How Does Carbon Content Affect Corrosion?

The effect of carbon on corrosion resistance boils down to several factors:

-

Increased susceptibility to pitting corrosion: Higher carbon levels can lead to the formation of carbides within the steel's structure. These carbides are less resistant to corrosion than the surrounding ferrite and can act as initiation points for pitting corrosion – localized corrosion that penetrates deep into the material.

-

Reduced chromium carbide precipitation: In stainless steels, chromium carbides are crucial for maintaining the protective passive layer responsible for corrosion resistance. Excessive carbon can consume available chromium, hindering the formation of this vital layer and leaving the steel vulnerable to corrosion.

-

Influence on microstructure: Carbon significantly impacts the microstructure of steel, influencing the formation of phases like pearlite and martensite. These phases can have different corrosion resistances compared to ferrite, making the overall corrosion behavior unpredictable.

What are the Exceptions?

While higher carbon generally reduces corrosion resistance, there are exceptions:

-

Specific alloying elements: In certain alloys, carbon can play a beneficial role in conjunction with other elements. Its interaction with other alloying elements can subtly alter the microstructure and corrosion behavior. However, this is highly dependent on the specific alloy composition and requires specialized metallurgical expertise.

-

Passivation layers: While generally detrimental, the precise control of carbon and other alloying elements can sometimes improve the formation of protective passive layers on the steel surface, leading to marginally improved corrosion resistance. This is an advanced application and is not a common practice for improving general corrosion resistance.

-

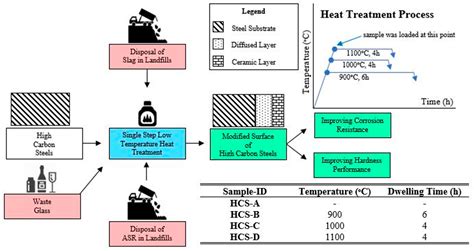

Surface treatments: Surface treatments like carburizing, nitriding, or coating can create a harder, more corrosion-resistant surface layer despite a higher carbon core. These treatments are used to enhance wear resistance and hardness but can also offer some benefit in corrosion protection.

What About Low Carbon Steel?

Low-carbon steel (mild steel), containing less than 0.25% carbon, generally exhibits better corrosion resistance than higher-carbon steels. The absence of large carbide precipitates and a more uniform microstructure contributes to its superior performance in many corrosive environments.

Why is Carbon Used in Steel if it Reduces Corrosion Resistance?

Carbon is a vital alloying element in steel primarily for its contribution to strength and hardness. The balance between achieving desired mechanical properties and maintaining acceptable corrosion resistance is a critical aspect of steel selection and design. In many applications, the need for strength outweighs the slight decrease in corrosion resistance introduced by a moderate increase in carbon content. Corrosion protection is then addressed using other methods, such as coatings, inhibitors, or cathodic protection.

How Can I Improve the Corrosion Resistance of Steel?

Several methods significantly improve steel's corrosion resistance, regardless of carbon content:

-

Protective coatings: Paint, galvanizing (zinc coating), or other surface treatments provide a barrier against corrosive environments.

-

Corrosion inhibitors: Chemical additives to the environment can slow down the corrosion process.

-

Cathodic protection: Applying an electrical potential to the steel prevents corrosion by making it the cathode in an electrochemical cell.

-

Alloying: Adding elements like chromium (in stainless steels) forms a passive layer, significantly enhancing corrosion resistance.

By carefully considering the carbon content and employing appropriate corrosion protection measures, engineers can design and select steels optimized for their intended applications, balancing strength, hardness, and corrosion resistance. The key takeaway is that while carbon can have some complex indirect effects, it's not generally used to improve corrosion resistance directly. Instead, other methods should be prioritized for bolstering corrosion protection.